One of the motors didn't turn more than 90 degrees or so. So this one would be the first to come apart. They are very easy to take apart once you figure it out. Start with the 6 screws on the back. They have thread locker on them, so they might be tight. Next take the back cover off. It is not attached to the shaft, but it has a bearing and a seal on it, so it is hard to move it the first 1/2" or so. Once you wiggle it up that far using flat head screw drivers, you can pull it off by hand.

The next step is to get the stator out. This can be a bit tricky, since the stator is a giant chunk of steel, surrounded by very strong magnets. I found that attaching it to my table vise with room underneath, then pulling very quickly upwards worked well. You want to go quickly because if you slowly apply pressure, it could get pulled down again. You want to get it out of the way of those magnets as soon as it loses grip.

This is the stator with the rotor already removed. You want the end of the flat part of the shaft to be touching the bottom of the vice, so that you can't pull the stator upwards. This works well because it also gives you plenty of room to grip the tire without risk of your fingers getting crunched.

And here's the culprit! This motor has a wave spring on both side of the shaft, presumably to apply a preload on the bearings. That's actually a nice feature, but this wave spring has broken into 3 pieces and is rubbing between the magnets and stator.

The magnets and stator are pretty scratched up from this, but it doesn't seem like it would affect the performance at all. I removed all the debris and put it back together and it seems to spin just fine.

On to the second motor:

This motor looks even nicer. It has some silastic holding the wires in place and darker insulation on the wires, which I assume means it's thicker.

The magnets still have their coating on them too, which is good. This motor also feels heavier. It looks like the stator and the rotor are both significantly heavier, but it turns out this isn't the case.

Motor 1 (Yuanxing branding on the tire):

My scale doesn't go quite high enough for the full motor, so I'll just add up these masses for the final mass. The total mass of motor 1 is 2.97kg

Motor 2 (Risingsun branding on the tire):

The total mass of motor 2 is 3.01kg. So they are almost the exact same mass. Despite looking heavier and having a stronger magnetic pull, the stator in motor 2 is actually lighter. The rotor in motor 2 is definitely heavier, though, and you can feel it. The outside surface seems to be thicker aluminum.

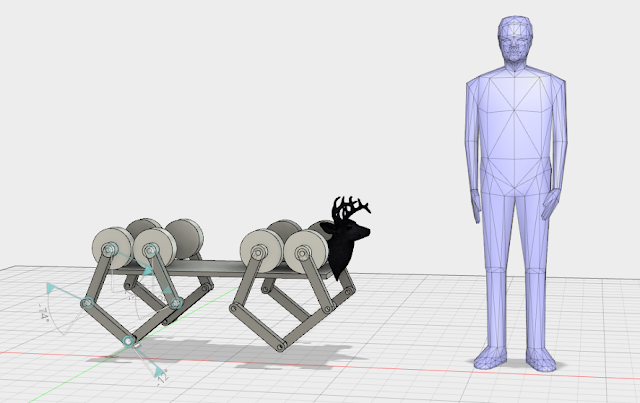

Having a low rotational inertia is pretty important for robotics applications, and these motors currently have a giant ring of rubber around the outside of them. Inertia scales as mr^2, so having a lot of mass around the outside is especially bad. Let's try to take the tire off!

That was easy! Here's a video of the process:

First I use a hacksaw to cut as far as possible without cutting the aluminum rim. Then use a sharp utility knife to cut as much as possible away. Then use a flat head screwdriver to pull the tire up and use the knife to cut it the rest of the way. The tire shouldn't be glued or attached in any way, so once there's a cut going all the way through, it should just detach.

The tire does seem to weigh quite a lot. Here are the two tires from the two motors:

So somewhere around 415g. That reduces the mass of the rotor from about 1.4kg to less than 1kg!

I think these will make excellent motors. Stay tuned for some testing with the ODrive.