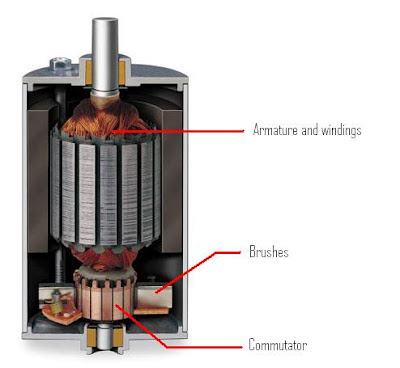

A key part that has always been expensive is the actuators that move the robot. These could be pneumatics, hydraulics, brushed motors, or brushless motors. In all of these cases, moving quickly, precisely, or with large forces meant expensive actuators. The best option has been brushed DC motors, but these are not very power dense, due to the mass of the brushes, the inefficiency of the commutation, and the limit of power that can flow through brushes.

Good motors got a lot cheaper when hobby rc brushless motors got more popular. You can buy a relatively high quality motor that can output multiple kilowatts of power for less than $50. Unfortunately most of these motors just aren't meant for robotics applications. They are usually wound for high speed rotation to power a propeller. They are actually ideal if you use a big gearbox (10:1 or more), but gearboxes are exceedingly expensive; many times the cost of the motor itself. There are "affordable" motors available with the specs needed, but they are still pretty expensive since they are for a niche market (at least $300).

Now imagine you are a 13 year old kid who loves Vine and [insert other Gen Z stereotypes here]. You don't care about all this dumb motor stuff. You just want a cheap hoverboard. So China obliged.

Hoverboards are super cheap. A pretty standard price is $150. So for $150 you get a frame, a gyro stabilizer board, a Lithium Polymer battery, 2 brushless motor controllers, and 2 super high torque brushless motors.

We don't really care about all the other stuff, but the part that's interesting is the motors. It turns out that these motors can output 20-30Nm of peak torque. That is an insanely large number. But what's more is the price. You can pick up a brand new motor on Amazon for $40. And if you order direct from China you can get it for less than $20! These motors are practically the same price as the raw materials going into them. Used motors go for around $15 on ebay.

What makes them so cheap? They certainly aren't high quality devices. You wouldn't want these motors anywhere safety critical. The main thing that makes them cheap is the insane quantity that they're manufactured in. Here's a picture from a seller on Alibaba who says they can supply 30,000 units per week:

This new source of high torque, low cost motors got me thinking about what I could do with one. So I came up with a few fun ideas.

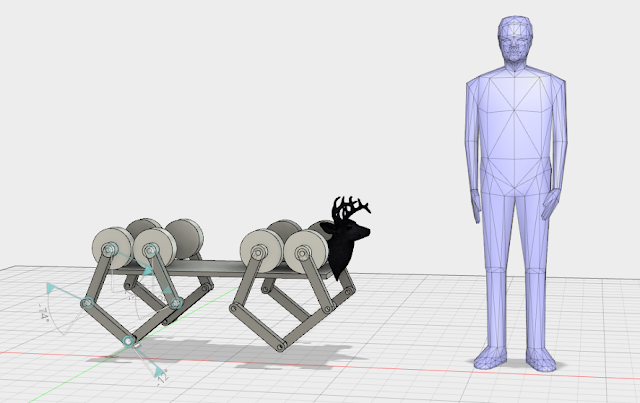

The first idea is something like Boston Dynamics Spot, or the MIT Cheetah.

This is using a belt drive system. This is similar to the newest version of the MIT Cheetah, which uses chain for the knee joint.

This is using a direct drive, delta type system. This version is very similar to the MIT mini Cheetah robot, or to the GOAT leg.

Both of these robots could be built for around $1000 including everything. That is dirt cheap compared to the hundreds of thousands of dollars that go into a Boston Dynamics or MIT robot.

Here's the approximate cost breakdown:

Hoverboard Motors: 8x $20: $160

Encoders: 8x $20: $160

ODrive Motor controllers: 4x $150: $600

Mechanical Parts: $150-$300

"Brains": $50-$500 (Beaglebone to Nvidia Jetson)

So the cost ends up being somewhere around $1k-$1.5k.

Another idea I had was a delta robot. Usually these robots have high speed motors with large gear ratios. This is probably technically better, but we're looking for cheaper, and gearboxes are expensive. So instead I think this would work great with no gearbox and 3 hoverboard motors.

I haven't put together a CAD sketch of what it would look like yet, but it would be basically exactly the same as any angular delta. Most 3d printers use a linear delta configuration, so check out industrial delta robots if you want to see what those look like:

Oskar from ODrive Robotics is working on a large robot arm using these motors, so that will be awesome too.

As I come up with more neat ideas for cheap robotics that can use these motors, I will post them here.

Thanks for the teardown! You're right, once you get the first plate up it's straightforward, but that was a useful pointer.

ReplyDeleteHave you seen, talking of the MIT cheetah, the Hobbyking cheetah? I think this guy works in the lab doing the cheetah, but he's building one from commodity parts - for MIT cruft values of "commodity"...

http://build-its-inprogress.blogspot.com/search/label/HobbyKing%20Cheetah